AL-CROSS

MOBILE LASER WELDING SYSTEM: MULTIFUNCTIONAL

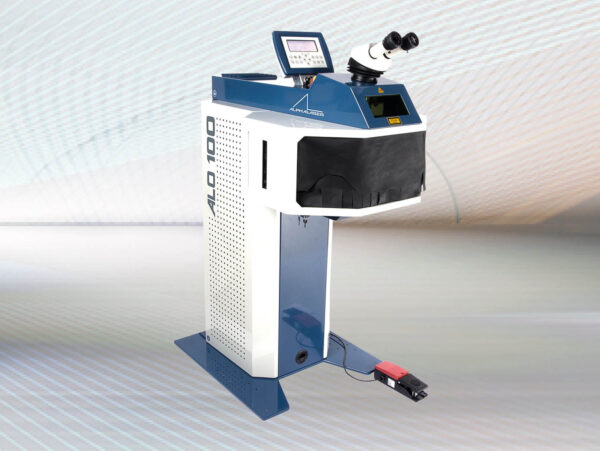

This new development focuses on robustness, quality, but also dynamics. A stable, solid housing and unique flexibility result in a very present appearance.

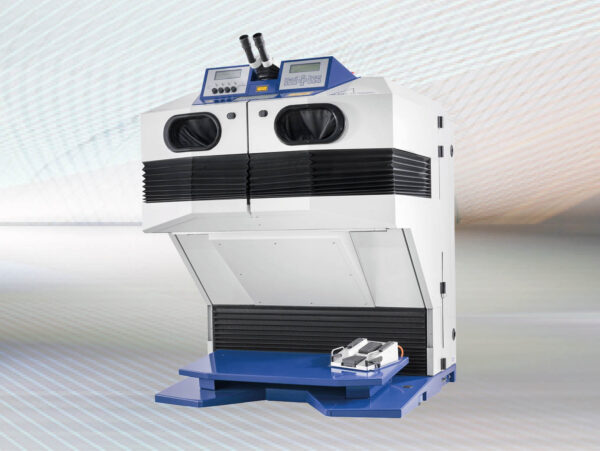

The external values: A robust housing with sturdy aluminum handles for reinforced impact protection of the edges offers multifunctional use of the laser welding system. Easy lashing and loading due to very strong recesses as well as integrated fastening options and winch eyes ensure safe transport. The 5th wheel on the laser device allows the gas bottle to be transported directly with it, which is very practical. Generous storage areas for this and that, special holders for welding wire, joystick, gas pedal, safety goggles and tools are useful helpers. You can also connect the suction unit to the integrated socket. The arm of the AL-CROSS can be raised to a very high position so that, if necessary, it is possible to carry out smaller welding jobs, e.g. on a car roof or overhead. Flexibility and mobility, the genes of most ALPHA LASER welding machines, are perfectly implemented.

HOW DOES THE LASER GET TO YOU OR TO THE PLACE OF USE?

The mobile welding laser, with its transport height of only 1.25 m (display foldable) finds space in trailers, VW Bulli, Multivan, Crafter, Caddy, Mercedes Vito, Sprinter and all other cars with a loading height of at least 1.40 m. Once on site, the AL-CROSS fits through standard doors.

Description

Your benefits at a glance:

- Working in very high (e.g. overhead) and low (e.g. on a pallet) positions possible

- Reinforced impact protection with sturdy aluminum handles and a robust steel housing

- New AL-Drive multifunction joystick: ergonomic and equally suitable for right- and left-handed users

- Intuitively operable software as well as apps for specific welding tasks

- Generous storage space and a functional design: perforated grid side panel for special holders for attaching tools, foot switches, etc.

- Tiltable HMI touch display for optimal visibility

- Open laser system – you work without limitation of the working space

- Work safely – the system meets performance level d

- Can be used quickly due to the short set-up times (positioning, fixing brakes, welding)

- Extremely flexible due to the multiple adjustment options of the laser head

- The narrow laser head also reaches deep into the workpiece

- No additional cooling required

Additional information

| Laser Type | Fiber Laser |

|---|---|

| Application | Laser Welding |

| Industry | Automotive Industry, Cast Repair, Industry Solutions, Mechanical Engineering, Sheet Metal Processing, Tool & Mold Making |

Data AL-CROSS

AL-CROSS_450F

| LASER | ||

|---|---|---|

| Laser Type / Wavelength | Fiber Laser, 1070 nm | |

| Average Power Output | 450 W | |

| CW power | 450 W | |

| Peak Pulse Power | 4.5 kW | |

| Pulse Energy | 45 J | |

| Pulse Duration | 0,2 – CW | |

| Pulse Rate/Frequency | Single pulse-100 Hz | |

| Beam parameter product at 50 µm | 2-3 mm * mrad | |

| Operating Mode | Pulsed / CW | |

| Welding Spot Ø | 0,2 – 3,0 mm | |

| Focusing Objective | 150 mm, others according to optics data sheet | |

| Pulse Shaping | Adjustability of the power curve within a laser pulse | |

| Display & Operation | Setting the laser parameters via touch display, multifunction footswitch, keyboard and AL-DRIVE | |

AL_CROSS_600F

| LASER | ||

|---|---|---|

| Laser Type / Wavelength | Fiber Laser, 1070 nm | |

| Average Power Output | 600 W | |

| CW power | 600 W | |

| Peak Pulse Power | 6 kW | |

| Pulse Energy | 60 J | |

| Pulse Duration | 0,2 – CW | |

| Pulse Rate/Frequency | Single pulse-100 Hz | |

| Beam parameter product at 50 µm | 2-3 mm * mrad | |

| Operating Mode | Pulsed / CW | |

| Welding Spot Ø | 0,2 – 3,0 mm | |

| Focusing Objective | 150 mm, others according to optics data sheet | |

| Pulse Shaping | Adjustability of the power curve within a laser pulse | |

| Display & Operation | Setting the laser parameters via touch display, multifunction footswitch, keyboard and AL-DRIVE | |